A Safety Shower Water Tempering System for the most demanding ambient temperature requirements and severe environmental conditions. Safety shower water tempering systems are custom designed to control safety shower water temperature for various ambient conditions utilizing custom engineered chillers and heaters.

Complies with American National Standard for Emergency Eyewash and Shower Equipment ANSI Z358.1 temperature requirements. Safety shower tempering systems are designed to regulate recirculating safety shower water to a tepid temperature range. Safety shower water outside of this range may enhance chemical reaction with the skin and eye tissues, and lower temperatures may cause hypothermia to the equipment user.

Compact, simple to install. The safety shower tempering system is delivered to you skid-mounted, pre-piped, and pre-wired with built-in temperature controls. On site, simply mount the unit, connect the piping, and wire an electrical power feed.

Cooling. Custom engineering allows for multiple options for reducing safety shower water temperature including heat exchangers, chilled water, or integrated chillers.

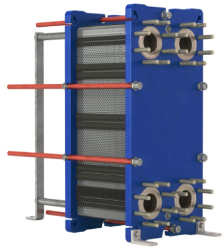

Double Wall Heat Exchanger. Mounted on the safety shower water tempering system skid, the double wall heat exchanger transfers heat carried by the safety shower water to the closed loop coolant system. Designed and manufactured to ASME pressure vessel code, the plate and frame or brazed plate heat exchangers are engineered and built for the most efficient operation and heat transfer. The double wall design ensures any leaks do not contaminate the circulating safety shower water.

External Chilled Water. If available, external chilled water sources may be used to decrease safety shower water temperature.

Air or Water Cooled Chiller. Direct and indirect refrigeration chiller circuits include hermetic scroll compressors; air or water cooled condenser options, brazed plated evaporators; and custom engineered refrigeration control options to accommodate low ambient, high ambient, and variable cooling capacity requirements. Indirect refrigeration chiller circuits also include an intermediate environmentally friendly propylene glycol circuit.

Heating. Heaters are available, including electric and steam operated, to increase safety shower water temperature in areas with low ambient temperatures.

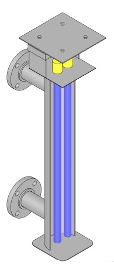

Ultraviolet Safety Shower Water Sterilizer. A UV sterilizer utilizes ultraviolet germicidal lamps to destroy microorganisms in the circulating safety shower water. The UV sterilizer includes quartz glass sleeves inside a stainless steel sterilizer chamber, high intensity ultraviolet lamps, lamp intensity sensor, and a UV controller and monitor.

Integrated Safety Shower Circulation Systems can be provided for a more complete safety shower water system. These systems include a safety shower water tempering system, safety shower water storage tank, water circulation pumps, control valves, and piping. Safety shower water storage tanks hold sufficient water to operate two safety shower and eyewash units simultaneously for fifteen minutes. Safety shower water pumps continuously circulate tempered water to individual safety shower/ eye wash units.

Automatic control with manual override for reliability and safety. The NEMA 4 or 4X custom electrical enclosure includes a main panel disconnect switch, motor starters for the pump, compressor, and fan motors; selector switch for the thermostatically controlled chiller and glycol pump; and selector switch for the thermostatically controlled circulation heater. Indicating lights, flow and refrigeration safeties, and multiple alarm options are available for your custom engineered electrical controls.

Custom Engineering allows for a wide range of options including monitoring alarm circuits, service valves, motor indicating lights, disconnect switches, explosion proof components, and various electrical power requirements.

Applications. Safety Shower Water Tempering Systems are custom engineered to the required environmental conditions, and are suitable for a variety of industries including petrochemical, chemical, metal fabrication, laboratory settings, and many others.

Call or email HydroThrift for a customized safety shower water tempering system proposal that will provide reliable tempered water to meet your safety shower water system requirements.