A heating solution for the most demanding equipment and process requirements. Industrial processing with hot adhesives, equipment and comfort space heating, food preparation requiring precise kettle temperature control, and sanitary water instantaneous-heating systems for pharmaceutical wash down are just a few of the applications solved with a HydroThrift heated water system. Continuously, efficiently and with minimum maintenance.

Completely automatic operation, reliable control of temperature. Whether the heating system is closed or open, and regardless of heating rates from gradual to instantaneous, you are assured that HydroThrift HW systems are designed to exceed your expectations. System pumps, tanks, valves, and temperature controls, ranging from economical, self-contained units to state-of-the-art electronic controllers, are selected to perform to your application's requirements. Operation is so simple, no assigned operator is needed.

Heat conversion from many sources. HydroThrift HW systems utilize low and high pressure steam, hot water, electricity, or heat recovery from any industrial process to heat water or water/glycol mixtures. Steam heated systems are complete with steam control valve(s) and steam trap(s). Electric heated systems include solid state power controllers to precisely regulate the heating. Hot water and heat recovery systems include pneumatic or electric actuated valves for temperature control.

Safe, reliable heat. HydroThrift systems are designed to provide years of trouble-free, low-cost service, even in tough environments. Closed loop systems use treated-water or a water/glycol mixture to continuously recirculate and provide economical and efficient heating. Heating system safety features include pressure relief valves, low-flow and high temperature alarms that automatically shut off the heating source, and the system components are all designed in accordance with ASME pressure vessel and piping codes.

Compact, simple to install. HydroThrift heated water systems utilize a compact pump package and either a heat exchanger or an electric water-circulation heater fully mounted and piped. Installed temperature and pressure gauges monitor pump and heat exchanger inlet and outlet parameters. Connect piping and a single power feed and your installation is complete.

Engineered systems boost heating efficiency. HydroThrift heated water systems are custom engineered to the application requirements for optimum heating efficiency.

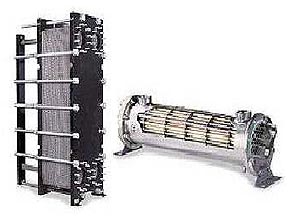

Heat Exchanger: Plate and Frame, Shell and Tube, or Electric. Mounted on the pump and control skid, the heat exchanger warms the recirculating fluid. Shell and tube heat exchangers are commonly used for steam or high pressure, hot water applications. Plate and frame heat exchangers provide closer approach temperatures to the heating fluid temperature and are applicable to heat recovery systems. When other heating sources are not available, HydroThrift HW systems utilize a three-phase electric circulation heater ranging from 1 to 450 kW capacity. Every heat exchanger is engineered and built for the most efficient operation.

Surge and vent tank. To minimize oxidation of heat transfer surfaces, the ASME code-welded surge and vent tank deaerates the heating fluid, and includes gauge glass, fill port, drain and vent valves.

System line gauges. Inlet and outlet gauges display pressure and temperature differentials for continuous monitoring of the heating system.

Automatic control. The UL508A designed and manufactured electrical enclosure contains motor starters, thermostatic controls, and an on-off selector switch for the circulating pump motors. The control circuit includes a control transformer for 110/1/60 and a power-on light.

Rugged, close-coupled centrifugal pump provides compact design. Couplings, alignment problems and attendant wear are eliminated in HydroThrift heating systems through the use of heavy-duty centrifugal pumps close-coupled on the motor shafts. Pumps are equipped with mechanical seals. Pump capacities are typically rated at 100 feet head with higher pump heads available as conditions demand.

Packaged pump and control skid. Pumps, electrical enclosure, vent and surge tank, piping, valves, gauges, wiring, thermostatic modulating valves (if required), and the heat exchanger are all completely factory assembled on a structural steel frame with a solid steel base plate.

Optional equipment. Custom engineering allows a wide range of options including dual stand-by pumps with automatic switch over; dual stand-by heat exchangers; low flow, low level, high temperature, and motor overload alarm circuits; service valves; and disconnect switches.

The bottom line is that HydroThrift heating systems provide continuous, high-efficiency heat transfer delivered at less initial cost and with better payback than other systems.