Open Evaporative (OE) Cooling System

Resources

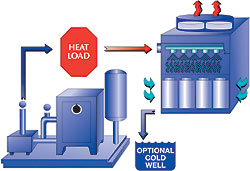

Open Evaporative Cooling Systems.In applications where an evaporative-type, closed loop (CE) glycol system cannot be used due to budget constraints or application considerations, an Open Evaporative (OE) cooling system will be offered. OE-type systems are more economical in terms of initial equipment costs; however, they may incur maintenance costs associated with scaling, fouling, and water treatment packages. OE-type systems are also operated where heat transfer fluids, such as glycols, are not allowed, and/or the cooling medium comes in direct contact with customer product, such as plastic and aluminum extrusions.

Completely automatic operation and control of flow, temperature and pressure.Packaged open cooling tower systems include a cooling tower and a pump and control unit. The pump and control module includes pump(s), motor starter(s), and thermostatic controls for the cooling tower fan motor(s). Operation is so simple, no assigned operator is necessary. The control package regulates temperature, flow rates, and heat exchange, using cooling tower water. Systems are available up to 2,500 cooling tower tons.

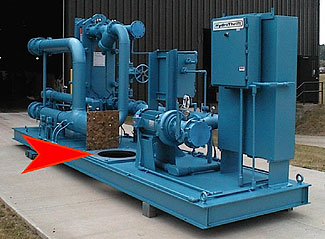

The pump and control unit is delivered to you mounted on a structural steel baseplate, pre-piped and pre-wired to the fullest extent possible. On-site, simply mount the cooling tower where it will have an adequate supply of clean, ambient air and sufficiently elevate the tower to allow the water to gravity drain to the pump suction or sump. Locate the pump and control module anywhere between the heat load and the cooling tower.

Integral, indoor water sumps. Where remote sumps are required or fluid mixing is needed for temperature control, packaged cold wells or combination hot well/cold well systems are available. These wells can be constructed of a variety of materials including carbon steel, stainless steel, and plastic. Skids using vertical turbine pumps are also available for use with in-floor/in-ground sumps. The skid is designed to cover the sump; minimizing necessary floor space.

Custom Engineered.HydroThrift open evaporative cooling systems are custom designed for your particular and exacting requirements. Although competitively priced with off the shelf type systems, your HydroThrift OE cooling system will incorporate pumps, electrical controls, flow controls and temperature controls which are selected specifically for your application. When selecting components and other design considerations, special attention is given to durability, serviceability, and system integration.

Polyethylene tanks available.High density polyethylene plastic tanks can be packaged on the pump and control unit to serve as the cold water well. The tank is isolated from piping stress with flexible connections. Tank sizes range from 150 gallons to 5000 gallons.

Cold weather operation approved. An optional bypass valve diverts returning water flow to the water sump or cold well rather than feeding it to the cooling tower. This is a necessary option for applications where climatic conditions may over cool or freeze the tower water during the winter.

Filter skids. Side stream filter skids are available to continuously filter fluid from the sump. These units take their suction from the tower sump or hot well/cold well, and separate the circulating particulate by means of a centrifugal separator and bag filter. This example includes a remote motor disconnect switch for the pump, whose motor starter is located in the main control panel. For add-on units and retrofits, a complete stand-alone filter skid can be manufactured.

Vertical turbine pumps. When cooling tower water is returned to an in-ground sump, a pump skid incorporating vertical turbine pumps can be designed and manufactured. The pump skid is the cover for the sump and incorporates a sump maintenance access door. A vertical turbine pump (not shown) draws from the sump and circulates cold water. A plate and frame heat exchanger that utilizes tower water on one side and glycol on the other provides the cooling for a closed loop circuit.

Fabricated steel hot well/cold well.This cooling system included two pumps, with an option for adding a third standby pump in the future. Cold water is pulled from the bottom of a large fabricated steel tank and sent to the heat load. Once the fluid has picked up the heat, it is directed to the cooling tower and then gravity feeds back to this cold well.

Strainers with automated blow down. This OE type system has a stainless steel cold well and automated strainers. Pressure differential is monitored across the strainers. When the pressure rises to the user's setpoint, automated valves open and flush the strainers.

The bottom line is that HydroThrift cooling systems provide continuous, high-efficiency heat transfer. And deliver it at less initial cost and with better payback than other cooling systems.